Today’s maintenance and facilities managers see the end result of their labors in practical ways. They witness production cycles reach their end points, on time and without incident. They see fleet vehicles arrive at their destinations safely, and they watch facility occupants smoothly going about their business.

It’s a satisfying feeling when good maintenance leads to great uptime results. But more often than not, managers are challenged to create a deliberate and ideal strategy for their organization’s big-picture maintenance goals—one that emphasizes the right balance of costs and benefits behind the scenes.

The best overall maintenance approach typically combines three common methodologies:

- Run to Failure—This is also known as corrective maintenance, and it involves replacing or attending to assets only after a failure has occurred. It includes reactive maintenance that might be done after a work request has been made.

- Preventive Maintenance—This plan organizes expected maintenance tasks into regular intervals, in such a way as to avoid failure and minimize downtime.

- Predictive Maintenance—More advanced than the others, this approach translates asset data and observations into action plans that offer nuanced maintenance actions, based on the asset’s current and expected condition.

The bulk of the work reflected in an effective plan, however, is often found in the preventive maintenance (PM) category. When it comes to preventive maintenance, enterprise asset management (EAM) software is the best tool to help managers keep their eyes on the end result.

ManagerPlus Lightning is an EAM platform built for modern PM needs. It offers the most powerful features available and helps you elevate your strategy and your business.

6 top EAM features for preventive maintenance

1. Fast, intuitive interface

Because time is probably your most pressing concern, you always need to look for ways to streamline your preventive maintenance plan. And that means being able to access your data anywhere, anytime, without always returning to your desk.

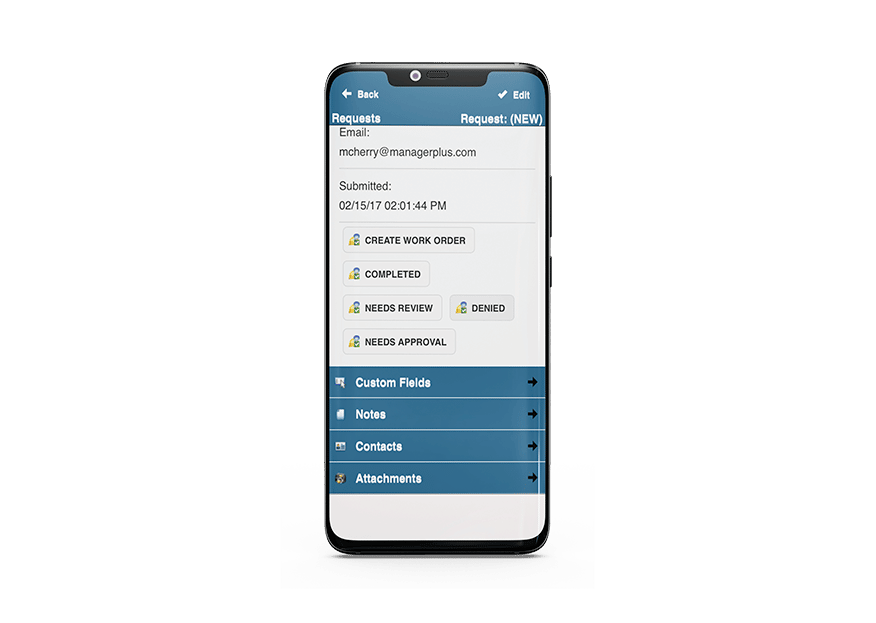

With mobile features, Lightning allows you to manage all your preventive maintenance tasks from a tablet or smartphone while you’re at a job site, en route or anywhere on the shop floor. Did a work order just come through requesting a fix on an air conditioning unit? With Lightning, you can see the action in real-time and keep the workflow going, even in remote areas.

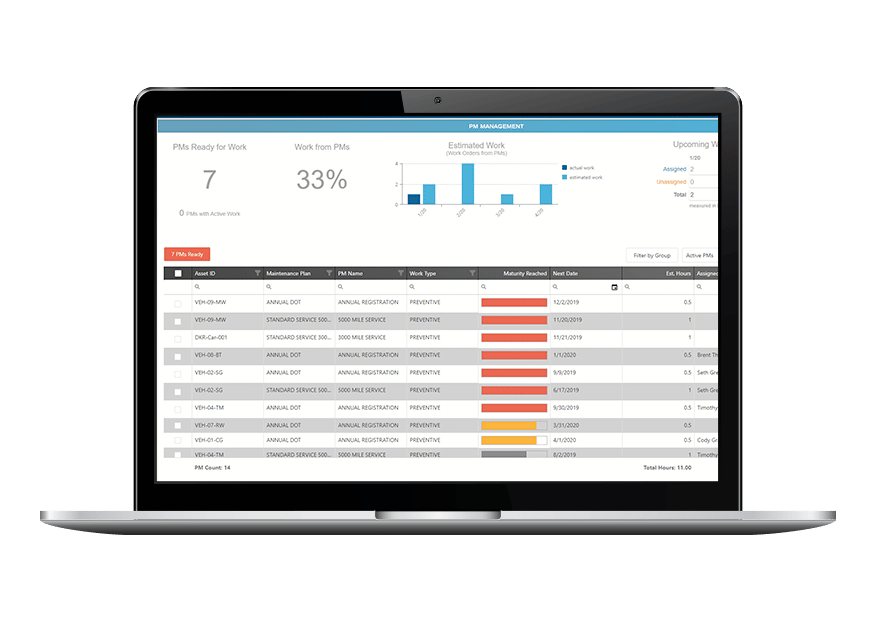

Because it’s hosted in the cloud, the Lightning interface surfaces your data quickly, whether you’re searching for a particular piece of information or organizing the week ahead. For example, if you need to find the number of open work orders associated with one particular asset, Lightning provides a detailed dashboard that includes exactly that information in just one click, without the need to run a report first.

Simply click on the asset and see a visual summary of everything that’s going on. The snapshot includes open work orders, the last PM task completed, activity timeline, cost information, asset performance, and more.

The asset’s dashboard also provides an easy-to-read graphic that visually demonstrates your work ratio: how much of your maintenance is preventive, reactive, or run-to-failure. Color codes also help demonstrate progress on your maintenance plan for each asset.

Even a new team member who has never used a computerized maintenance management system (CMMS) before can instinctively use the Lightning interface and understand any asset in detail.

2. A platform designed for your specific assets

Major industries that use EAM platforms generally include construction, manufacturing, transportation, facilities management, agriculture, infrastructure, energy and healthcare. EAM software works well for many other specialties, but these are the biggest user categories.

Yet, for each category, the assets can vary widely. Construction firms might need to manage maintenance for backhoes, carry lifts or knuckleboom loaders that move from site to site. Meanwhile, manufacturing firms might need to optimize conveyors, chillers or packing machines running within a large production facility. Each type of asset has different maintenance needs, and each individual asset is on a different schedule.

ManagerPlus’ preventive maintenance software is designed to serve the toughest industries with asset-specific data fields that capture exactly the type of information you need. Even more so, Lightning allows you to create asset groups and hierarchy, add your own notes and integrate with other software applications for a truly custom solution.

3. Ability to adapt quickly

Keeping up with change is one of the fundamental challenges of business. A merger or acquisition can reshape your company overnight. A new product line or new investment can upturn your previous strategy. Even organic growth—while a positive development—can cause some disruption.

A maintenance or facilities manager needs to be able to pivot quickly, especially when bringing new assets online. Lightning makes it easy to add equipment, machines and vehicles to the platform then drag and drop tasks to update your PM schedule.

Daily schedules can fluctuate when technicians take time off or when priorities shift unexpectedly. With Lightning, you can reorder and reorganize schedules in batches, by task or technician, to ensure productivity never lags.

4. Automation

Lightning eliminates the need to continually rekey repetitive tasks in the system interface, thanks to its powerful automation tools. Need to schedule oil changes on 20 fleet vehicles every 30,000 miles? Schedule it once, and Lightning automatically prompts the appropriate notification or work order to cue the task when it needs to be done. Need to replace the blades on a cutting machine or inspect an air conditioning unit every 30 days? Lightning will make it happen.

Automated work orders ensure nothing falls through the cracks. They also provide extra efficiencies because you can plan your preventive maintenance schedule long-term and prepare for the future in terms of staffing, inventory and budgets.

Automation is one of the key reasons why firms make the switch from isolated spreadsheets and hard copy files to EAM systems. Instead of relying on memory or chasing after stacks of paper, an EAM like Lightning modernizes your preventive maintenance practices, resulting in time and money saved.

But automation is more than just generating work orders. With Lightning, you can create customized business intelligence reports and schedule them to arrive in your inbox as often as you like. Tracking the inventory of personal protective equipment across your whole enterprise? One report can bring that data to your fingertips on a daily basis.

5. Inventory management

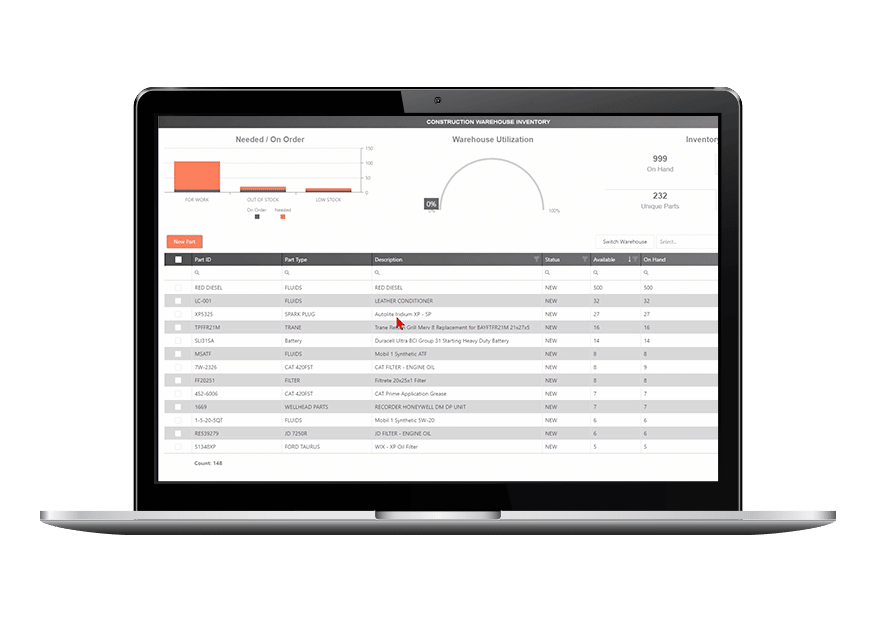

There’s no doubt that preventive maintenance can be stalled when the right parts and materials aren’t available. Juggling the stock on hand, ordering new items and managing the inventory budget can seem like a full time job in itself.

ManagerPlus Lightning makes the entire process easier. Add vendors, images, part lists and warranty information all in one place. You can even speed up access to the data by scanning barcodes with your smartphone. Then when it’s time to reorder, you’ll have everything you need.

On a single dashboard, see what’s in stock, out of stock or on order, as well as the price of each item, its location and the full value of your current inventory.

The power of Lightning goes even further to help you manage inventory levels proactively, ensuring you have enough of what you need. When parts and materials are used to fulfill work orders, Lightning can prompt you with notifications when it’s the right time to restock, based on your preferences.

If you’d always like to have two filters on hand for every HVAC unit on your asset list, Lightning will ensure your teams are never caught short. If your machine’s replacement parts require an especially long lead time, Lightning can deliver notifications earlier to ensure timely delivery.

6. Robust reporting

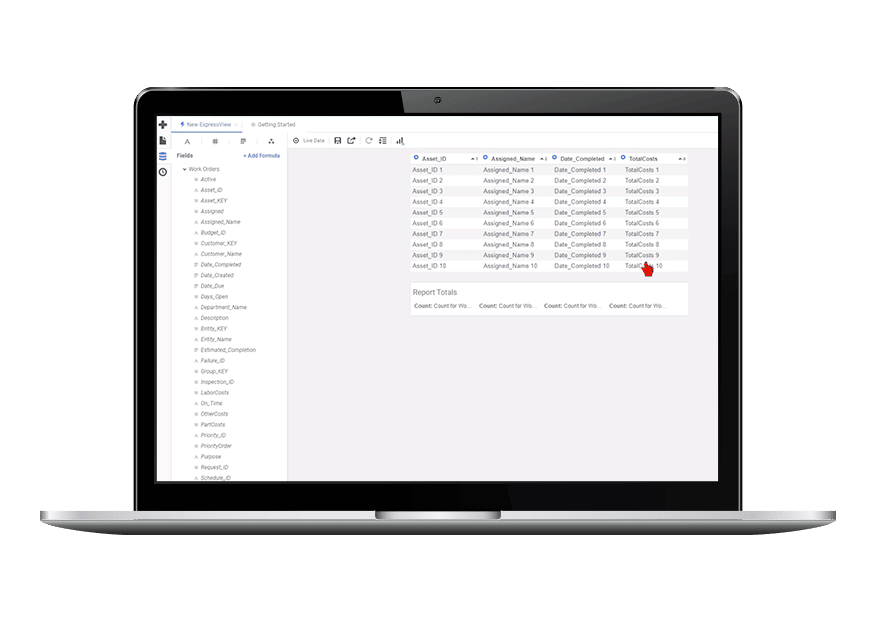

Preventive maintenance strategies improve when you understand your assets better. With ManagerPlus Lightning’s advanced business intelligence reporting tools, you have all the insights you need to customize your PM schedules and get the best possible efficiency out of your assets.

For example, you can prepare a forecast of your upcoming workloads, including what’s already been assigned, what needs assignment and how many hours of expected work are on deck. Plan for the day, the week, the month or even further out. Take a retrospective look at workloads, too, by creating a report with your chosen parameters.

Reporting is the key ingredient that will help you advance your PM strategy. By tracking real-world data, you can find new opportunities to improve productivity, save money or just make your life easier.

What to expect from Lightning

Preventive maintenance backed by an EAM system is one of the smartest ways to increase your asset life cycle and reduce downtime. ManagerPlus Lightning continues to innovate new features so you can modernize your strategy and grow your business.

Here’s what you can expect from Lightning:

- Quality and safety: Your investment in data-driven preventive maintenance strategies results in greater safety for your teams and better product quality, resulting in less rework. More efficient production means lower costs.

- Greater efficiencies: Lightning’s automation allows you to save time, and time is money. Get the most out of every hour on the job and every asset in your enterprise by streamlining your PM tasks with Lightning.

- Improved asset utilization metrics: Better asset use will increase production capacity and reduce the cost of asset replacement over time.

- Better bottom line: Leverage business intelligence reporting to manage budgets. Streamline processes to increase productivity. Optimize uptime for greater business profitability.

Ready to experience ManagerPlus Lightning in action? Watch the demo video to see the top preventive maintenance features and more.