In our first installment on Overall Equipment Effectiveness (OEE), we looked at how you calculate the availability metric (Availability = Operating Time / Planned Production Time) using data from your CMMS system.

In this installment, we’ll take a look at the next component of OEE: Performance, which is calculated as:

Performance = (Operating Time/ Total Pieces)/ Ideal Cycle Time

Ideal Cycle Time, sometimes referred to as Nameplate Capacity, Theoretical Cycle Time, or Design Cycle Time, is basically just a measure of what a given piece of equipment should be capable of producing under ideal circumstances within a given timeframe.

In manufacturing settings, this is usually measured by throughput—how many parts/pieces a machine produces. In other industries, such as construction, this can be somewhat more difficult to measure, but virtually any measure of output/productivity is workable.

In ManagerPlus’s maintenance management software , throughput (or cycle counts, in our example) can be easily set up as a log value, which can then be set to trigger a work order automatically if output falls outside of the acceptable range.

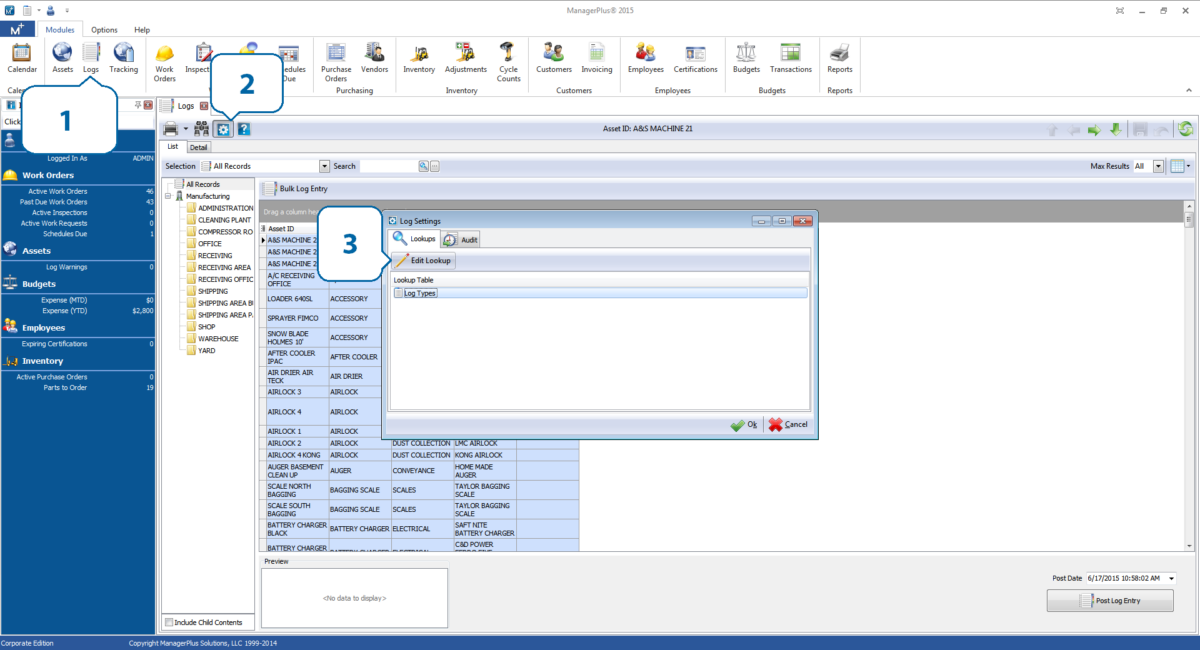

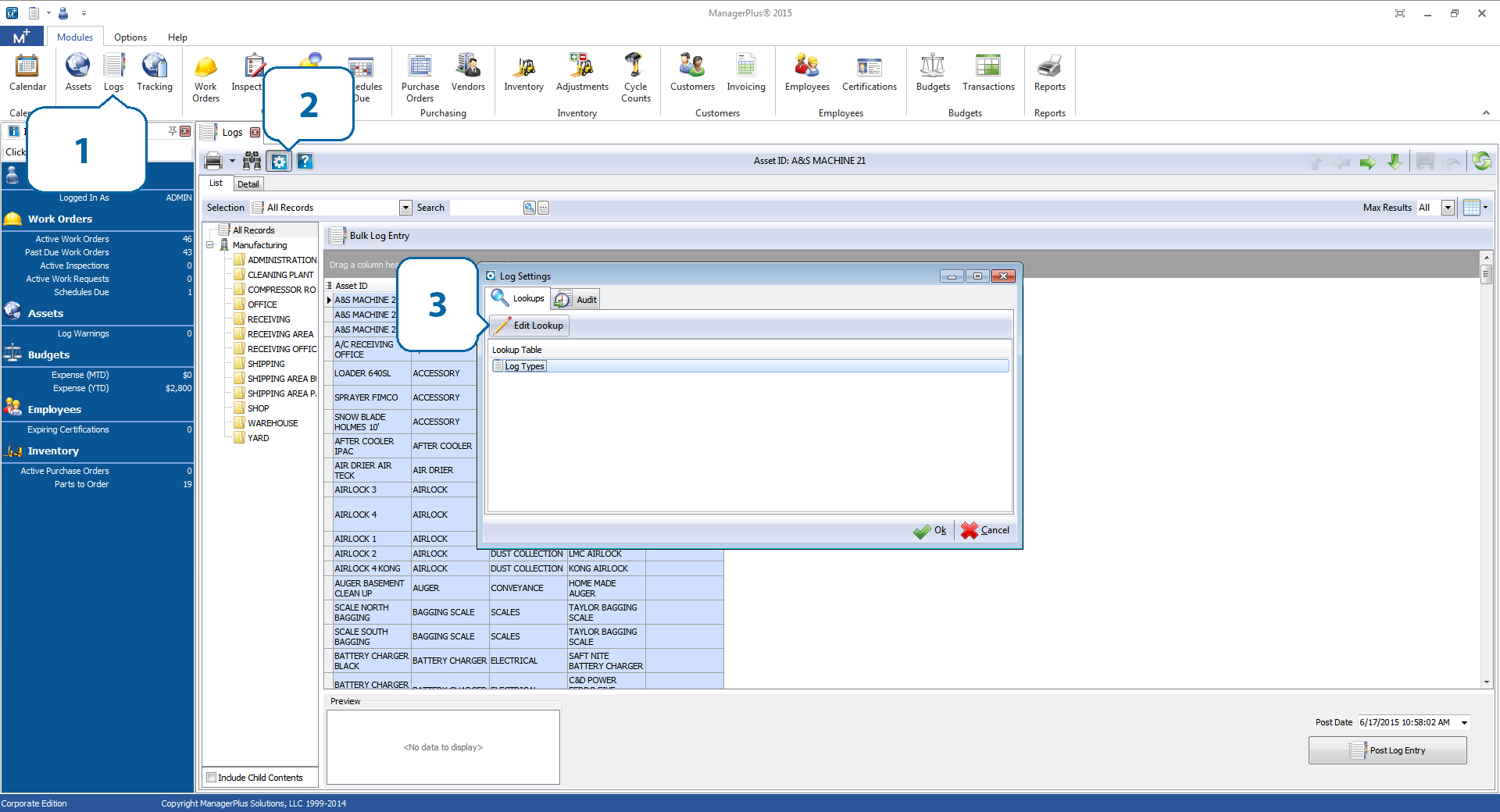

First, open ManagerPlus and click on the “Logs” module (1). Within the Logs module, click on the gear icon (2) in the upper left hand corner of the tab, select “Log Types” and click “Edit Lookup” (3) in the Log Settings window.

Continue reading “OEE: The Role of Maintenance in Equipment Performance”

Continue reading “OEE: The Role of Maintenance in Equipment Performance”