If you’ve been considering implementing facility sustainability initiatives at your facility, but don’t know where to start amid the complex tangle of “green” standards, practices, and technologies, you’re not alone.

Over the past decade, facility management has gone from a fringe ivory tower concept to a full-blown mainstream movement. Take the Leadership in Energy and Environmental Design (LEED) standards for example. The rating system, introduced in 1994 as a single standard applying strictly to new construction projects, has grown into a complex framework encompassing interior design, neighborhood development, building operations and maintenance, and industry-specific standards for schools, healthcare facilities, and retail stores among others.

This growth in complexity might help explain why just 7,000 projects worldwide have earned LEED certification—leaving the impression that only high-profile projects with major funding and resources are capable of joining the ranks of the “green” elite.

Unfortunately, this impression has helped turn facility sustainability into an all-or-nothing proposition for many facility managers, when in reality, there are numerous inexpensive, easy to implement measures that can lower costs, improve health, and minimize environmental impacts in any facility.

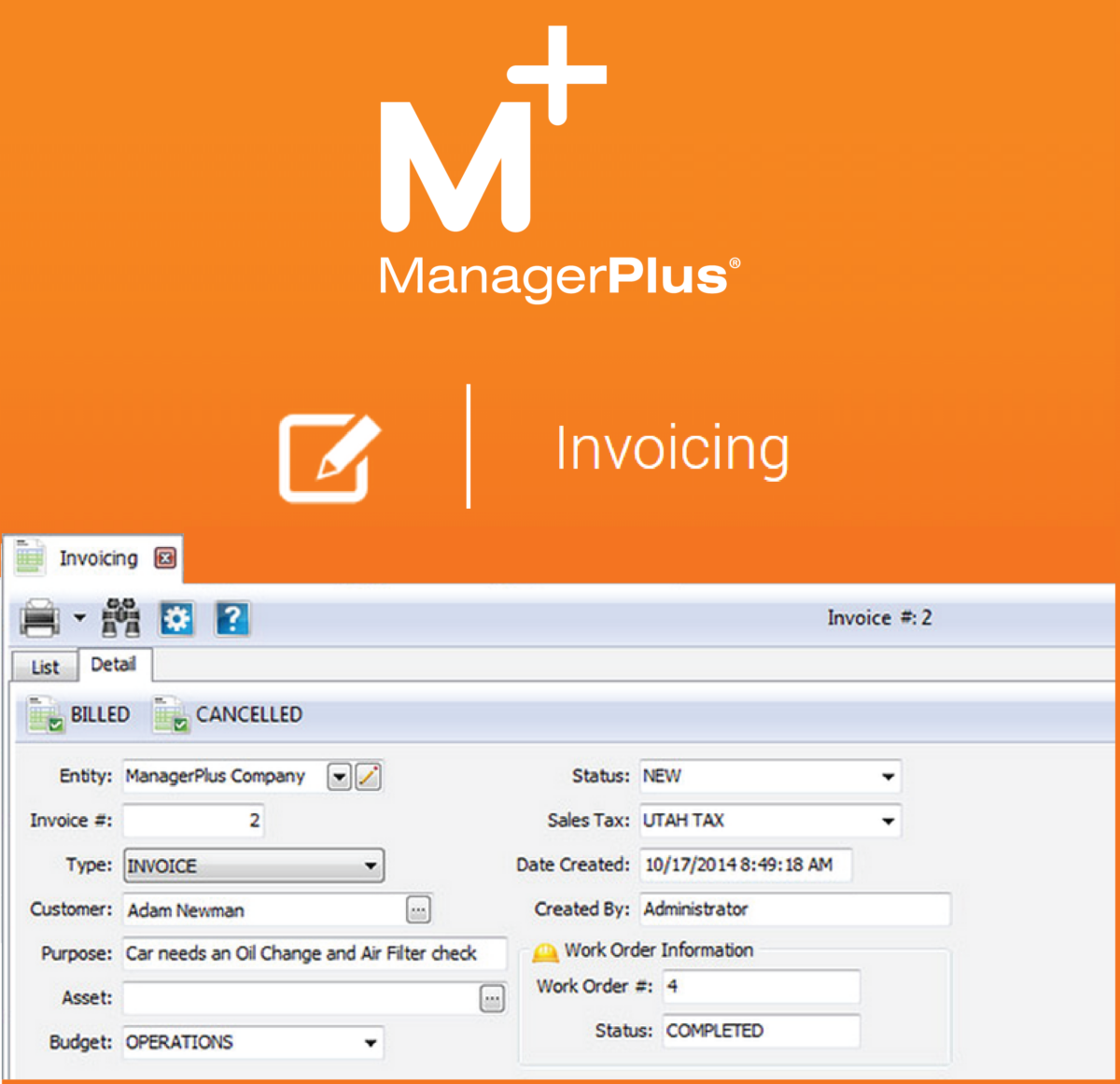

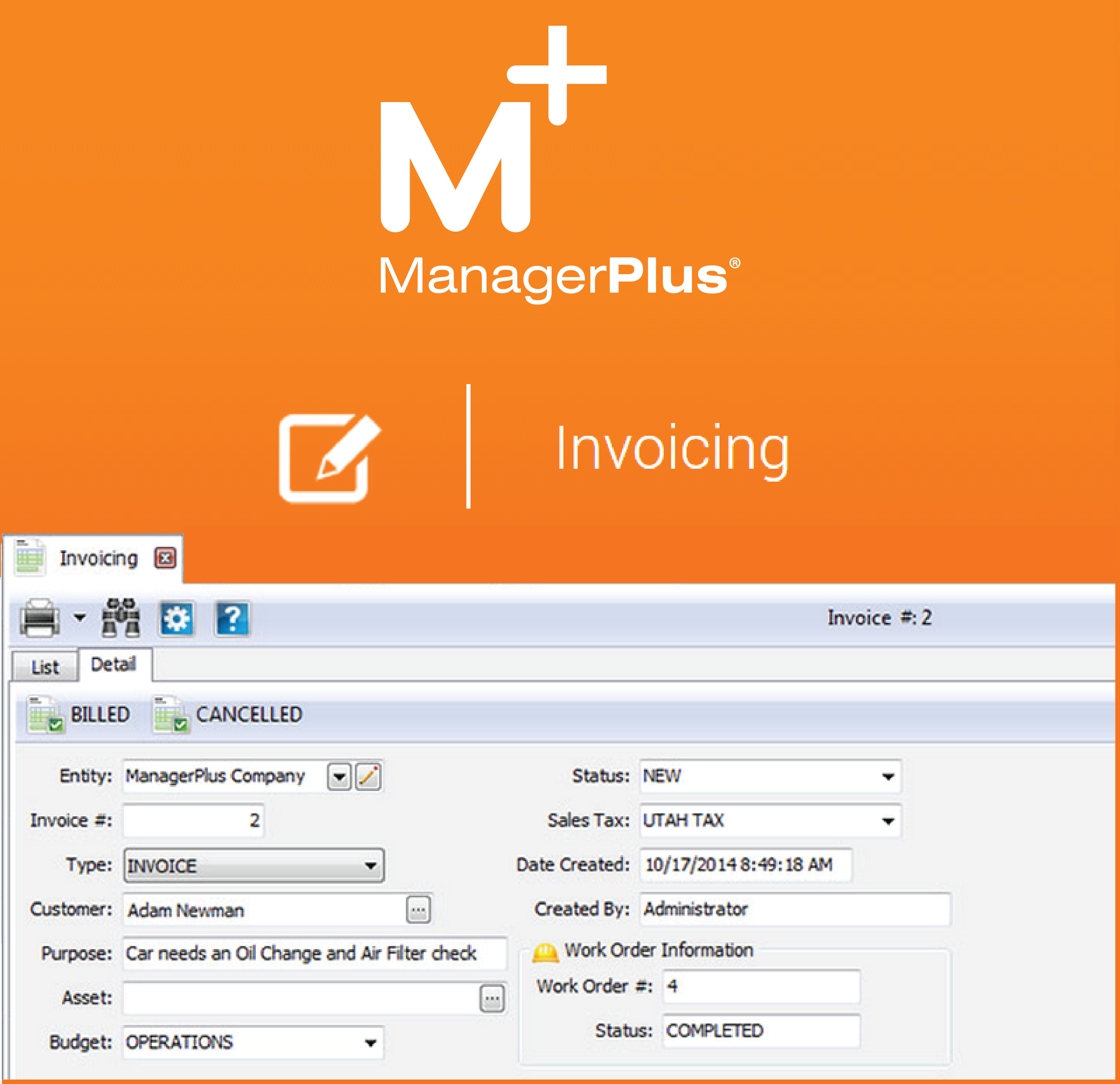

The key is to use tools like facility management software to maximize the efficiency of existing resources, implement sustainable best practices, and upgrade parts and equipment with new eco-friendly versions.

+ Make the most of what you have. Conservation is one of the core tenets of the facility sustainability movement. Facilities that proactively maintain their assets not only prevent costly emergency breakdowns—they also catch minor problems early, before they cause major inefficiencies and waste. Continue reading “Facility Sustainability: ABCS of Advanced Maintenance”